Is preventative maintenance more of a hobby or a way of life at your manufacturing plant?

Like modern medicine, the idea of proactively taking a role in the “health” of electrical equipment will provide great value to a company. If an illness is approaching, the human body has the ability to provide early warning signs. The same can be said about electronics. While the human body has the ability to cure itself of certain illnesses, if a defect appears on the plant floor with machinery, it is just a matter of time before the electronics ultimately fail. Unfortunately, electronics do not have the ability to “heal” themselves.

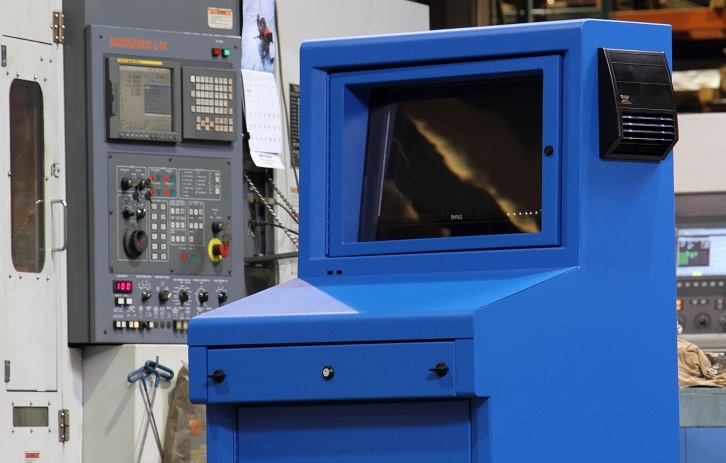

The majority of workers will not exert much concern for maintenance until the process is no longer working as it should. Paying little attention to corrective maintenance, on a regular schedule, will cause electronics housed in an industrial computer enclosure to not perform as well as they did upon the original installation. According to the Library at AutomationDirect.com website, “Heat inside an enclosure can decrease the life expectancy of controlling units such as your PLC, HMI, AC drives and other items. Excessive heat can cause nuisance faults from your electrical and electronic components… Heat will also change the expected performance of circuit breakers and fuses, which can cause whole systems to shut down unexpectedly.”