When deploying computer enclosures in a hot, harsh environment, thermal management considerations should be at the top of the project list.

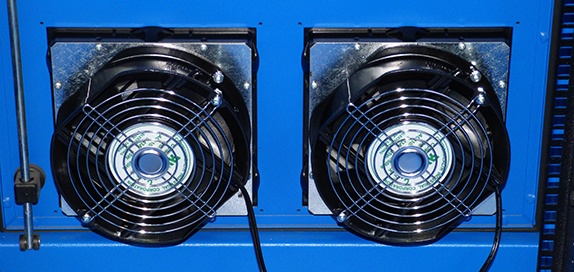

Thermal management is an important item to contemplate. Electronics always generate heat and that heat needs to be abated. An overheated enclosure can be detrimental to vital equipment. In many instances, filtered fan systems are the perfect way to cool the enclosure.

As you might imagine, many sizes of fans and filters are available on the market and should be carefully analyzed, including the air performance rating. In addition, some fans are designed to run continuously, while others can be efficiently combined with a thermostat to only turn on when needed. It is also important to take into account the location of the fan and/or fans on the pc or computer enclosure. Location could be the difference between cooling and just blowing hot and harmful air!

5 Cooling Tips for Filtered Fan Systems

- Install electronic components - housed in the enclosure with the highest heat dissipation - towards the top of the enclosure, where excess hot air will be forced out through the exhaust. The website, doityourself.com, describes the simple concept of warm air, “When one installs an exhaust fan, it is recommended that he or she places it as high up as possible. The closer it is to the [top], the better. This is because warm air rises upward, and hence, if the exhaust fan is lower down, it will miss a significant part of the hot air … and as a result it will not manage to operate as effectively. The more hot air reaches the exhaust fan[,] the more it will be absorbed and eliminated from the room.”

Install electronics with the most critical temperature sensitivity near the fan intake. This will provide the coolest air flow (great tip for printers, which tend to generate a good amount of heat when continually in use).

Install electronics with the most critical temperature sensitivity near the fan intake. This will provide the coolest air flow (great tip for printers, which tend to generate a good amount of heat when continually in use).

- The fan system should blow ‘cool’ air into the computer enclosure and keep dust and damaging contaminants out, creating a positive pressure inside the enclosure. Positive pressure is critical when keeping an enclosure free of dust and contaminants.

- Inquire what level of filtration is required with the fan system. According to Air Quality Engineering, a micron is “a millionth of a meter (μm). To put in perspective, the average human hair is 150 microns in diameter while dust is typically 5 to 10 microns in size.” For example, a 10 micron filter is commonly used on industrial fan systems. However, for manufacturing environments that have very fine dust or debris in the air, a 3 micron filter, a finer filtration, may be required. Keep in mind, the finer (more dense) the filtration media, the less air you will be able to move through the filter/cabinet.

- The intake and exhaust cutouts on the enclosure need to be sized as large as the fan motor and filter. High quality enclosures generally have cutouts pre-installed for factory authorized filtered fan systems. This makes installation and delivery more efficient at the factory or during a field installation.

Thermal management is the most important factor in determining whether electronics will have a lengthy or short life. It is important to get the optimum operating life from electronic equipment. Fan systems should posses a high-efficiency design, state-of-the-art electronics, and pleasing aesthetics. In the end, filtered fan systems are easy to install and almost maintenance free! They can be the best thermal management solution for the job, depending on the ambient temperature and the heat generated on the inside of the enclosure.

For more information, visit our related blog posts:

Using Filtered Fans to Cool Computer Enclosures

Effects of Heat & Humidity on Computer Enclosures

Managing Heat Load for Computer Enclosures

3 Problems the RIGHT Thermal Management Eliminates for PC Enclosures

HAVE QUESTIONS?

LET US KNOW HOW WE CAN BEST ASSIST YOU! CONTACT AN 'ITSENCLOSURES EXPERT' AT 1-800-423-9911 -OR- SEND US AN EMAIL: INFO@ITSENCLOSURES.COM