Installing a purge control on a computer or pc enclosure is a popular method for deploying expensive electronics in hazardous areas.

Throughout the world, classified areas are commonplace in manufacturing environments. The classified areas exist to prevent hazardous gases and dust from igniting in the presence of electronics. Based on the National Electrical Code (NEC), there are two divisions used to describe classified areas. Division 1 is more hazardous than Division 2, because dangerous elements are more likely to be present in these areas. Therefore, Division 1 requires a higher level of protection than Division 2 locations.

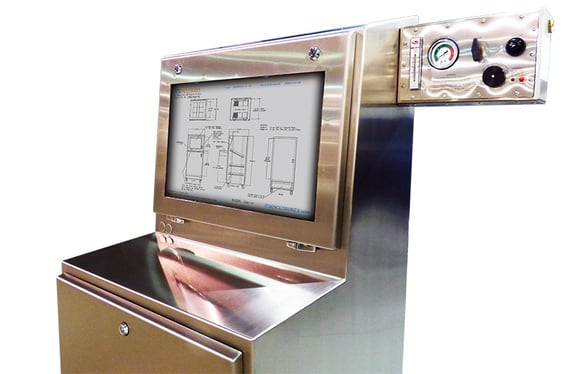

Installing a purge control on a computer or pc enclosure is a popular method for deploying expensive electronics in hazardous areas. The enclosure is purged with compressed air or an inert gas. Because the interior is always under a positive pressure, purge systems prevent harmful gases, dust, and dirt from entering the enclosure.Purge controls allow a NEMA 4 or 4X enclosure to be used in a Division 1 or Division 2 area. Note, depending on the area, modifications to the enclosure will likely need to occur to be suitable as a pressurized cabinet. A standard NEMA 4 cabinet is designed to prevent the external environment from harming the internal electronics. However, this generally means that this enclosure rating is unsuitable for retaining internal pressure. Modifications are almost always necessary when using a standard “off the shelf” product. To prevent a computer enclosure from deforming under the pressure, manufacturers will add additional hinges, gasket, and locks to prevent a reaction to pressure on large surface areas.

To ensure the enclosure is pressurized, a non-explosive gas is pumped into the cabinet to “purge” or flush out any existing contents and ensure that all areas of the enclosure contain only the purged gas. On average, it takes between 5-10 volume changes to ensure the enclosure is properly purged.  According to the article, ‘Daisy Data Displays' X-Purge Control Gets Redesigned,’ purging is essential in hazardous area, “Enclosure purging systems eliminate the possibility of combustible gases within sealed, pressurized enclosures in hazardous areas by ensuring that their atmosphere is essentially nothing but the purge gas, typically nitrogen… After the cabinet is completely purged, the exhaust modules shut off to maintain gas pressure where the original system would continue to demand gas. If leaks are not excessive, this conserves gas; and if the leakage rate is high, the system lets you know.”

According to the article, ‘Daisy Data Displays' X-Purge Control Gets Redesigned,’ purging is essential in hazardous area, “Enclosure purging systems eliminate the possibility of combustible gases within sealed, pressurized enclosures in hazardous areas by ensuring that their atmosphere is essentially nothing but the purge gas, typically nitrogen… After the cabinet is completely purged, the exhaust modules shut off to maintain gas pressure where the original system would continue to demand gas. If leaks are not excessive, this conserves gas; and if the leakage rate is high, the system lets you know.”

In areas that are warm, special precautions are also necessary to maintain optimum operating temperatures. The use of compressed air is normal for supplying air to the purge control. The use of a vortex cooling unit is very common with purged computer enclosures. Avoid using a fan or blower to cool electronics, which generally requires ducting air that may actually draw in flammable gases.

Always remember: a purged enclosure requires a constant supply of compressed air or an inert gas and cannot be opened during normal operation. The explosion protection is achieved by warding off potentially explosive atmosphere from any source of ignition. As long as positive pressure is maintained, no harmful elements will be able to enter the enclosure, thus creating a safe and secure environment for workers.

For more information:

- Commonly Asked Questions for Purged Computer Enclosures

- Computer Enclosures for Hazardous Manufacturing Environments

- Essential Features for NEMA 4X Computer Enclosures

HAVE QUESTIONS?

LET US KNOW HOW WE CAN BEST ASSIST YOU! CONTACT AN 'ITSENCLOSURES EXPERT' AT 1-800-423-9911 -OR- SEND US AN EMAIL: INFO@ITSENCLOSURES.COM